Clutch Can Have a Long Life --Howo Truck Clutch Maintenance.

As we know that the clutch can be separated as push type and pull type. For the pull-type clutch, the structure is simple, the efficiency is higher and the service life is longer. Therefore, for HOWO trucks, especially the high-powered vehicles, the 371 hp HOWO, the clutch type is the pull-type clutch.

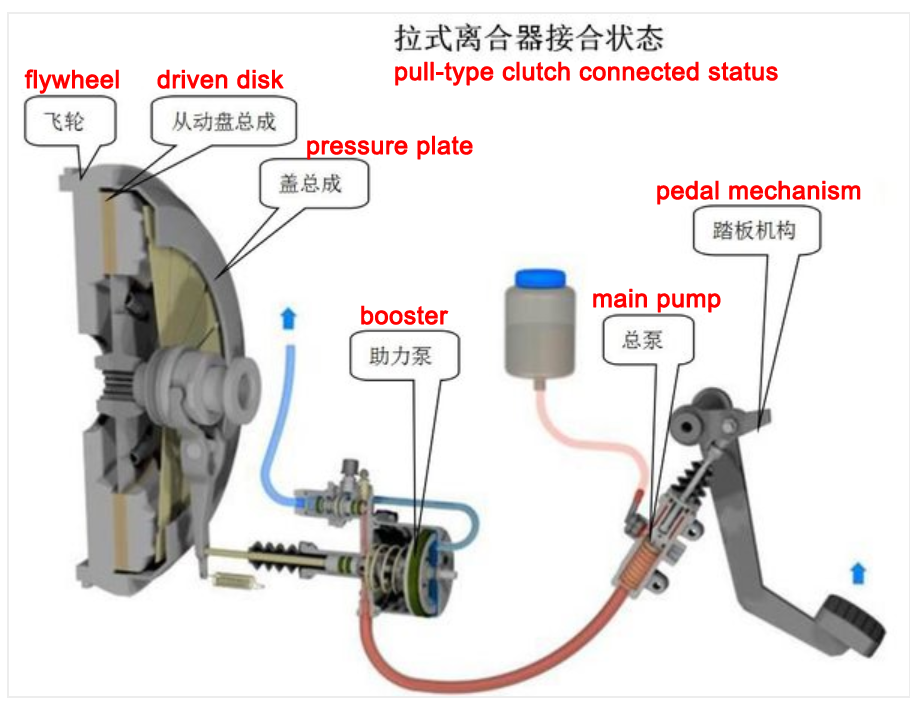

First, let's look at how it works. Let's look at the status of engagement:

When the pressure plate and the flywheel (howo truck parts) are bolted to the engine, the clutch is in the engaged status. At this point, the spring leaf on the clutch cover causes the platen face and the flywheel to tightly press the clutch plate between them. When the clutch cover assembly and the flywheel rotate, the driven disk assembly and the transmission drive shaft are driven by the frictional torque on the friction plate on the driven disk assembly

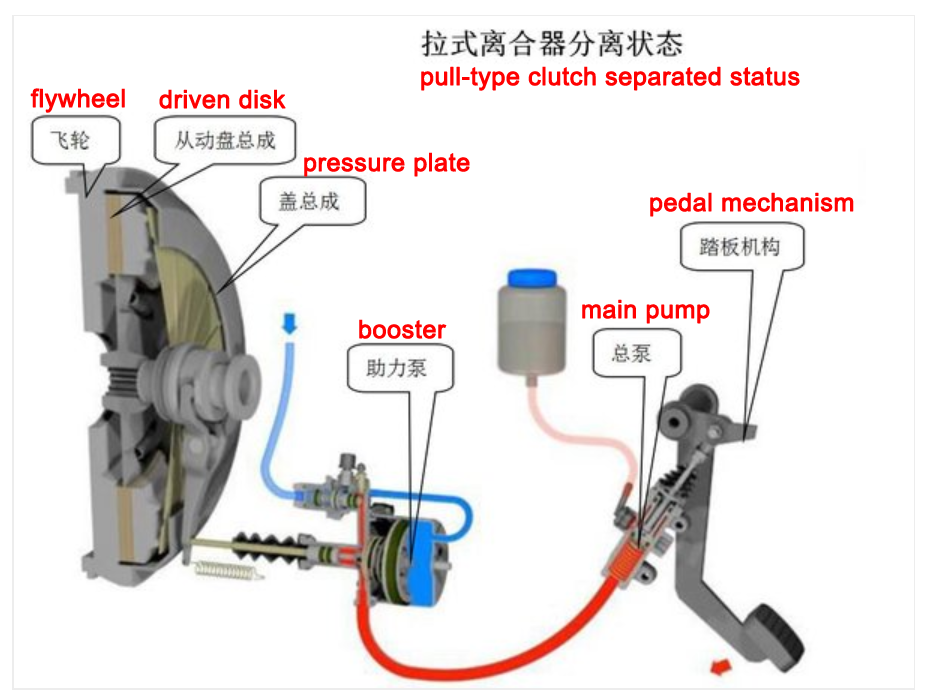

Then look at the separation status:

When the gear is to be engaged or shifted, the clutch pedal is first stepped down, the clutch oil is passed through the clutch master cylinder and the clutch cylinder to push the fork to the left, and the fork is moved to the right by the lever principle. (howo truck parts catalog pdf)

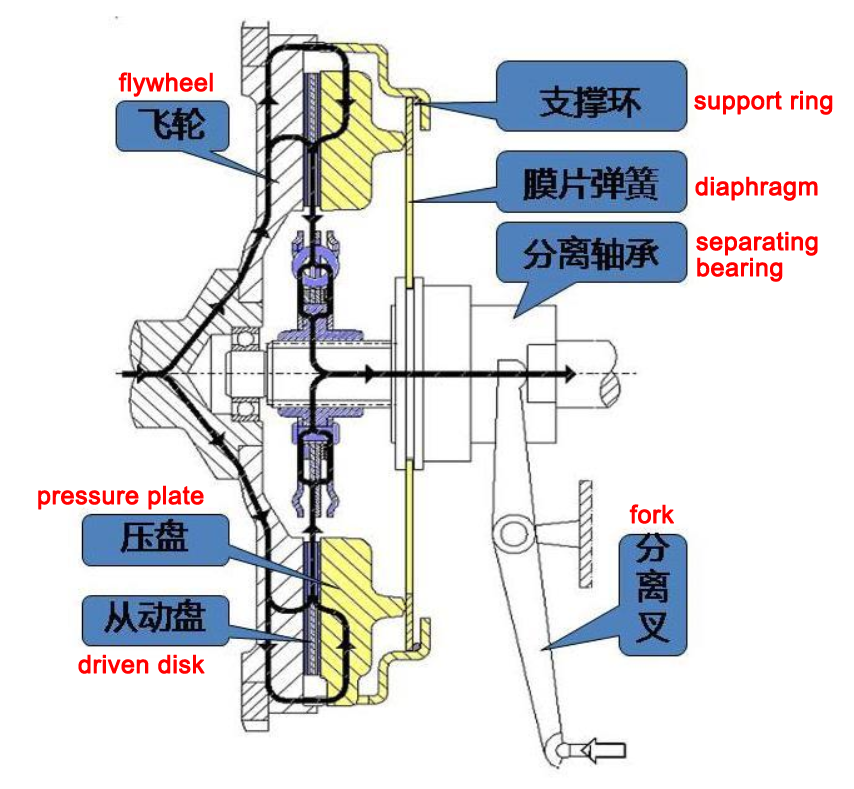

Through the above explanation, it may not be clear that how the flywheel, the clutch disc, the pressure plate and the release bearing are assembled or how they moved. See image below:

The separation bearing and the diaphragm spring are interlocked. When the booster pushes the separation fork to the left (the direction indicated by the arrow in the lower right corner), the lever moves the separation bearing to the right by the lever action, and the separation bearing drives the pressure plate diaphragm spring to turn counterclockwise with the support ring as the center, to move the pressure plate to the right, thereby separating the pressure plate, the clutch plate and the flywheel.

After learning how they are working, let's look at the faults that are often encountered in clutch systems. Clutch slippage and vehicle trembling are two common failure phenomena in clutch systems. Through two forms below, the fault phenomenon, possible causes and solutions can be listed for everyone, so that we can prevent it in advance and improve the operating habits or problems.

Clutch slip

Symptom: The clutch plate is worn or ablated.

Possible cause: Frequent use of semi-coupling operation causes excessive wear of the clutch plate.

Maintenance method: pay attention to usage habits under standard load conditions.

Symptom: The surface of the clutch is burnt or the surface of the platen is blue.

Possible causes: Under heavy overspeed and heavy load conditions, the clutch is frequently used or often in a semi-coupling state.

Maintenance method: pay attention to usage habits under standard load conditions.

Symptom: The free travel distance of the clutch pedal is too small.

Possible cause: Pre-energizing force on the separation spring of the diaphragm spring.

Inspection method: adjust the pedal free distance and separate the gap between the bearing and the diaphragm.

Symptom: The frictional contact surface of the clutch assembly is oily.

Possible cause: The transmission input shaft oil seal fails and leaking oil.

Inspection method: replace the transmission oil seal.

Trembling when starting

Possible cause: The pressure plate or flywheel surface is not flat.

Inspection method: check and replace damaged parts.

Possible cause: The pressure plate separation refers to uneven force, bias, and softness.

Inspection method: check the pressure plate or separate bearing, replace if damaged.

Possible cause: The clutch pedal is not fully returned.

Inspection method: Check the clutch pedal mechanism to see if there is any fault.

Possible cause: Diaphragm breaks.

Inspection method: replace the pressure plate.

Possible reasons: The second gear starts, not operated properly. Maintenance method: pay attention to operating habits.