How to Drive a Sinotruk Howo Truck --Howo Truck Manual

Recommended Page: How to Drive a Sinotruk Howo Truck --Shift Gears for All Howo Gearboxes

Running-in Period for New Trucks

The running-in mileage is about 2000 kilometers. Like the tractor from the factory to the dealer, the running-in period has been carried out, so when the car reaches to the user, the running-in has been almost completed. But even so, the truck that has just arrived in the user's hands still needs to be treated carefully (howo truck parts).

- The average truck break-in period is 1500-3000km.

- Generally speaking, the running-in objects include all moving parts. But the most important thing is the engine. Of course, the running-in of the gearbox and the rear axle is also very important.

- The key during running-in period is to be gentle.

- Avoid stepping the throttle to bottom;

- Avoid using the same gear for a long time

- Avoid sudden braking.

- Avoid overloading, the best load is 60% to 70% of the standard load

Vehicle Start

Battery & Switch

Before the engine start, check if the main switch of the battery is engaged. Avoid unnecessary engine start to protect the battery.

The main switch of battery shall be off if the vehicle is parked for long or the electrical system is maintained. Do not disconnect the main switch with the engine running.

Do not release or remove the battery terminal end with the engine running.

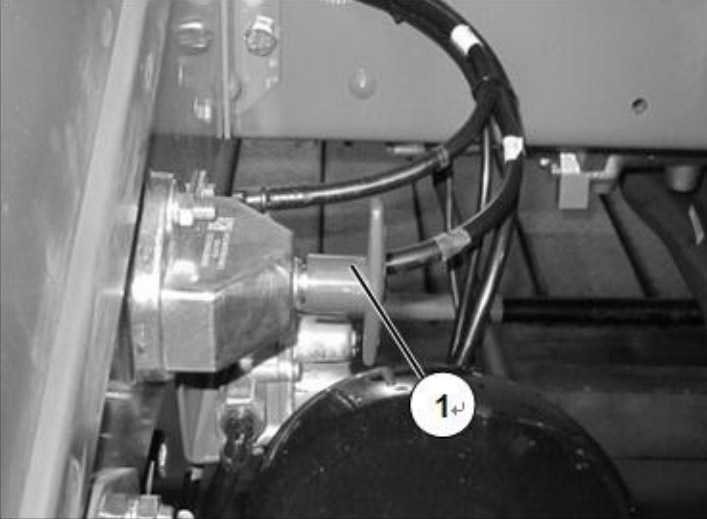

Engage the switch

- Power supply can be connected to the whole truck by turning the handle①, outside the battery box, anticlockwise to a horizontal position.

Disconnect the switch

- Power supply can be disconnected to the whole truck by turning the handle①, outside the battery box, clockwise to a vertical position.

Keys

- Do not turn off the key switch in driving and always set it to “II”.

- Remove the key before leaving, even for a short time.

- Set the key to “II”, related lamps will be on in turn: Position lamp /brake lamp/reversing lamp/ rear fog lamp/working lamp/ front fog lamp/lower beam lamp…the cycle goes on and on.

Meanwhile, the instrument indicator lamps will be on one by one, and the instrument pointer will oscillate from 0 to MAX repeatedly, and the information display will shift between “Drive display”, “Input information display” and “Output information display”. If a system fault is detected, related fault will flash on the information display (recycling display for more faults).

- Do not turn off the key switch in driving and always set it to “II”.

- Remove the key before leaving, even for a short time.

- Set the key to “II”, related lamps will be on in turn: Position lamp /brake lamp/reversing lamp/ rear fog lamp/working lamp/ front fog lamp/lower beam lamp…the cycle goes on and on.

Meanwhile, the instrument indicator lamps will be on one by one, and the instrument pointer will oscillate from 0 to MAX repeatedly, and the information display will shift between “Drive display”, “Input information display” and “Output information display”. If a system fault is detected, related fault will flash on the information display (recycling display for more faults).

Engine Ignition

Step one: step on clutch to bottom

Step two: turn the key to “III”, engine starts.

Step three: stop turning the key.

Note:

- The time of turning key shall not exceed 15 seconds, if starter works for some seconds and the engine is not started, please check for reasons of this failure.

- Lamps will be off after the checking/warning functions are completed. Do not start the vehicle until the fault display mark “STOP” on the driver display disappears.

- Startup the vehicle till the system pressure reaches over 0.55 MPa (5.5 bar), the warning lamp is off and alarm buzzer stops ringing, air pressure reaches 0.7 MPa (7 bar).

Step one: step on clutch to bottom

Step two: turn the key to “III”, engine starts.

Step three: stop turning the key.

Note:

- The time of turning key shall not exceed 15 seconds, if starter works for some seconds and the engine is not started, please check for reasons of this failure.

- Lamps will be off after the checking/warning functions are completed. Do not start the vehicle until the fault display mark “STOP” on the driver display disappears.

- Startup the vehicle till the system pressure reaches over 0.55 MPa (5.5 bar), the warning lamp is off and alarm buzzer stops ringing, air pressure reaches 0.7 MPa (7 bar).

Warming up the Vehicle

1- Make sure wheel differential and axle differential is shut off.

2- Do not forget to adjust the driving mode, empty load, light load, standard load, and heavy load.

It saves a lot of fuel for you.

3- Do not push fuel pedal deep at this stage, it may wear the pistons sets, turbo, and air compressor.

4- Warm the truck in 5 minutes. If longer than 5 mins, there may cause carbon depositon in injectors.

2- Do not forget to adjust the driving mode, empty load, light load, standard load, and heavy load.

It saves a lot of fuel for you.

3- Do not push fuel pedal deep at this stage, it may wear the pistons sets, turbo, and air compressor.

4- Warm the truck in 5 minutes. If longer than 5 mins, there may cause carbon depositon in injectors.

Gearbox Operations

Please refer to page, there is very details how to shift gears for all Howo trucks:

How to Drive a Sinotruk Howo Truck --Shift Gears for All Howo Gearboxes

PTO

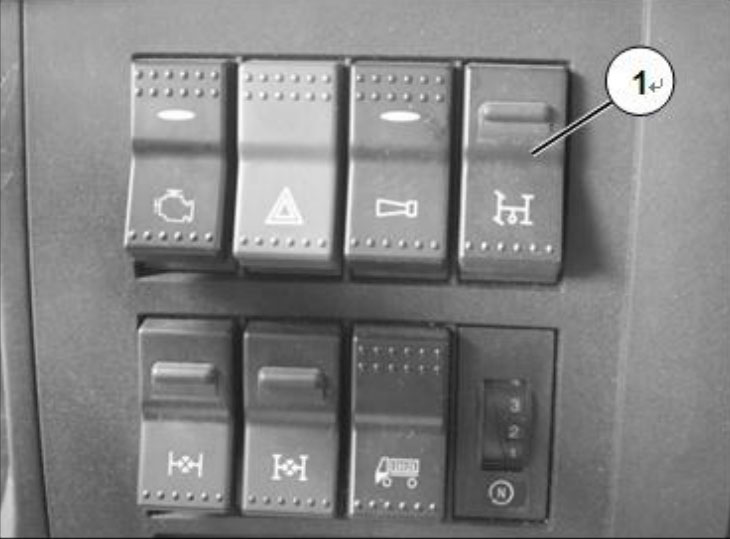

Engagement of power take-off

- Push down the clutch pedal,press down the power take-off switch ①, engage the power take-off (at this time, PTO indicator lamp on the dashboard

will light up); Then shift to low gear and loose the clutch.

Disengagement of power take-off

- The power take-off can be disengaged by pushing down the clutch pedal,then resetting the power take-off switch ① and, after about 3 s, loosening the clutch pedal. At the same time indicator lamp on the dashboard will light off.

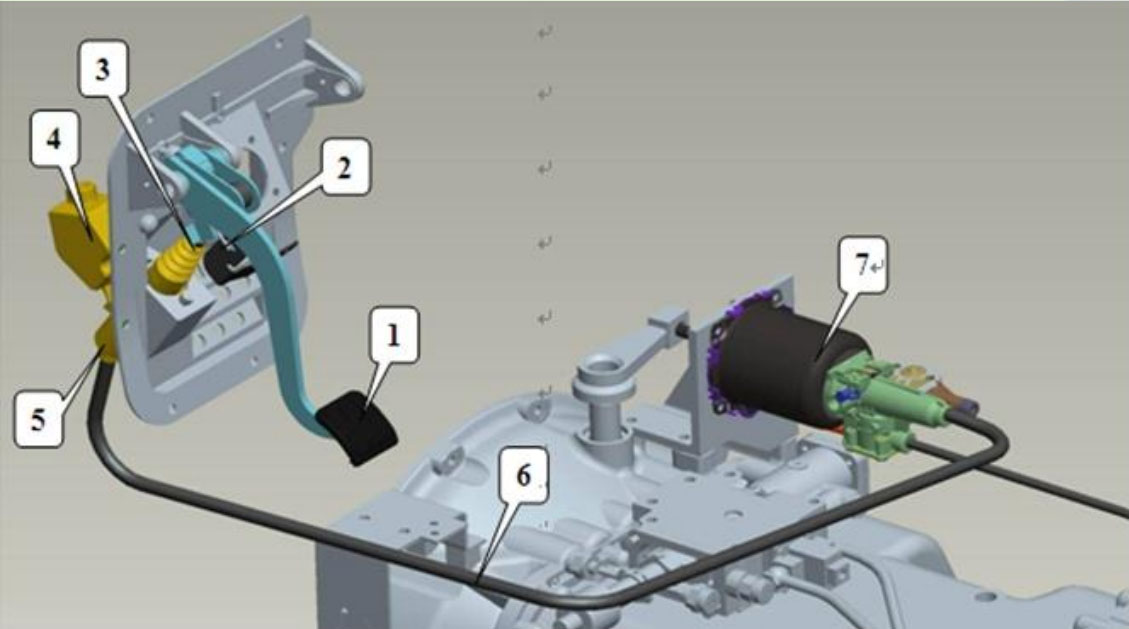

Clutch

1.Clutch Pedal Assembly. 2. Return Spring. 3. Push Rod of Clutch Driven Cylinder.

4. Clutch Oil Reservoir Tank. 5. Clutch Master Cylinder. 6. High Pressure Oil Pipe.

7. Clutch Booster Cylinder.

The clutch operating system is applied with hydraulic control and air-assistant structure.

When depressing the clutch pedal, the push rod of master cylinder drives the piston to move forward and the oil is pushed to flow into the chamber of booster cylinder along the oil pipe, then its piston drives the booster cylinder to move forward hydraulically and pneumatically, then rocker arm is pushed and then the clutch released (howo truck parts catalog pdf).

4. Clutch Oil Reservoir Tank. 5. Clutch Master Cylinder. 6. High Pressure Oil Pipe.

7. Clutch Booster Cylinder.

The clutch operating system is applied with hydraulic control and air-assistant structure.

When depressing the clutch pedal, the push rod of master cylinder drives the piston to move forward and the oil is pushed to flow into the chamber of booster cylinder along the oil pipe, then its piston drives the booster cylinder to move forward hydraulically and pneumatically, then rocker arm is pushed and then the clutch released (howo truck parts catalog pdf).

Two Diffs

Engage of inter-wheel differential lock.

• If both inter-wheel and inter-axle diff locks are needed, please engage the inter-axle lock first.

• Vehicle must be completely stopped.

• Push the upper part of inter-wheel differential lock switch, then the rear axle inter-wheel differential lock engages. Its indicator lamp is on.

• Carefully push the throttle pedal and then speed up slowly.

• Do not steering while any diff lock is on, remember to disengage it when not needed.

Disengage the inter-wheel differential.

• Vehicle must be completely stopped.

• Push clutch pedal.

• Push the lower part of inter-wheel differential lock switch, then the inter-wheel differential lock disengages, the indicator lamp of instrument panel will be off.

Engage of inter-axle differential lock.

• If both inter-wheel and inter-axle diff locks are needed, please engage the inter-axle lock first.

• Vehicle must be completely stopped.

• Push the upper part of inter-axle differential lock

switch, then inter-axle differential lock engages. Its indicator lamp is on.

• Carefully push the throttle pedal and then speed up slowly.

• Do not steering while any diff lock is on, remember to disengage it when not needed.

Disengage the lock

• Vehicle must be completely stopped.

• Push clutch pedal.

• Push the lower part of inter-axle differential lock switch, then the inter-axle differential lock disengages, the indicator lamp of instrument panel will be off.

Braking

The brake pedal will act on all vehicle wheels through two independent circuits.

It has the working pressure of 0.75 MPa, with the cutoff pressure of the built-in pressure regulating valve of the dryer of 0.81 MPa (8.1 bar).

As the circuit one acts on the rear axle (or double rear axle) wheel and the circuit two acts on the front axle wheel; when one air reservoir pressure of two circuits drops to below 0.55 MPa, the air reservoir pressure indicator lamp will be on; in such case, please immediately stop the vehicle and find out the pressure drop cause.

Continuous full stroke brake operations in a short time will also make the pressure drop to below 0.55 MPa.

For exhaust braking, it will be affective when terms below are met:

1-Exhaust braking switch is on.

2-Clutch is not pushed, and gear is not at Neutral.

3-Rotation speed of engine is above 800 rpm.

Tips for Economy driving

- Economical engine speed is below 2300 rpm.

The green area on dashboard shows the economical rotation speed; when the engine rotation speed is higher than 2,300 r/min, the red engine rotation speed over-limit indicator lamp on dashboard will be on.

- The fuel consumption increases by 5% with every tyre pressure drop of 1 bar below the normal.

- If well handled, skip unnecessary gears.

- Gearbox with synchronizers will help you to save fuel, as two steps on clutch for shifting gears is not needed.

Engine Stop

If the engine has kept running with high load, the coolant temperature will be too high, in this case, do not shut off the engine immediately after arrival, instead, have it idly run for 3-5 minutes and stop it till the coolant temperature drops, otherwise the engine may be damaged.

1-Set the transmission to neutral.

2-Parking brake on.

3-Anticlockwise turn the key to “0”‖. Engine stops.

4-Turn off the battery switch.